"Material handling" encompasses the industry dedicated to providing solutions for the protection, control, movement, and storage of materials. The primary objective of material handling equipment is to enhance productivity while ensuring a safe work environment. This field is particularly crucial in plants and warehouses, and it extends its influence across various industries.

Material handling equipment can be categorized into four distinct types: storage and handling equipment, engineered systems, industrial trucks, and bulk material handling.

Examples of equipment from these respective categories include storage racks, conveyors, forklifts, and cranes. Storage racks are shelf-like structures utilized by both manufacturers and homeowners to store, display, or organize various items. Conveyors are employed in industrial and commercial facilities to transport materials from one location to another. They can function as simple transportation mechanisms or as components of larger assembly systems.

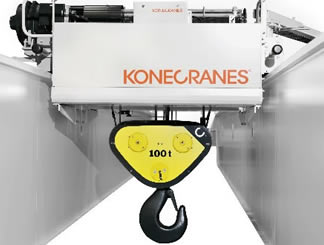

Forklifts and cranes are designed to lift and move heavy or bulk materials. Forklifts, being smaller and more mobile than cranes, primarily lift, load, and transport heavy pallets. Cranes, on the other hand, are typically used to hoist and move loads of various sizes, with the capability to lift up to 1,000 tons. Another distinction between forklifts and cranes is their lifting mechanisms. Forklifts use a driver-controlled lift mechanism that slides underneath loads, similar to a dolly. Cranes lift materials using a hook or hoist attached to a chain or wire rope.

In the world of material handling, a variety of equipment plays pivotal roles. This includes hydraulic lifts, balers, palletizers, pallets, hose reels, and automated guided vehicles (AGVs). Hydraulic lifts, harnessing the power of liquid mechanics, effortlessly raise, lower, and support hefty materials that human strength alone cannot manage. These devices are especially crucial in handling bulk materials.

Balers, on the other hand, are masters of compression, binding and compacting materials into manageable forms. They find their primary applications in agriculture, waste management, and recycling, transforming chaos into order. Palletizers are the diligent workers of the shipping world, adept at loading and unloading pallets both before and after shipment. Available in manual, automatic, and robotic versions, they ensure the efficient movement of goods.

Pallets themselves are the unsung heroes of storage and transportation, providing stackable platforms that keep products organized and mobile. Hose reels, though secondary in nature, are essential for maintaining industrial hoses. Acting as giant spools, they keep hoses dry, kink-free, and neatly organized, with models ranging from manual to automatic. AGVs are the autonomous navigators of the plant, self-guided vehicles that transport materials or perform tasks such as parts assembly, seamlessly moving through the facility to enhance productivity.

Often, manufacturers enhance their material handling equipment with advanced analytical systems to efficiently track and manage their inventories.

Material handling equipment is a cornerstone of the assembly and manufacturing processes across numerous industries. To dive deeper into the specific equipment and machines utilized in material handling, explore the sections below. Each section includes a list of manufacturers who produce or supply these vital pieces of machinery. Visit their websites or contact them directly to discover how they can meet your needs.